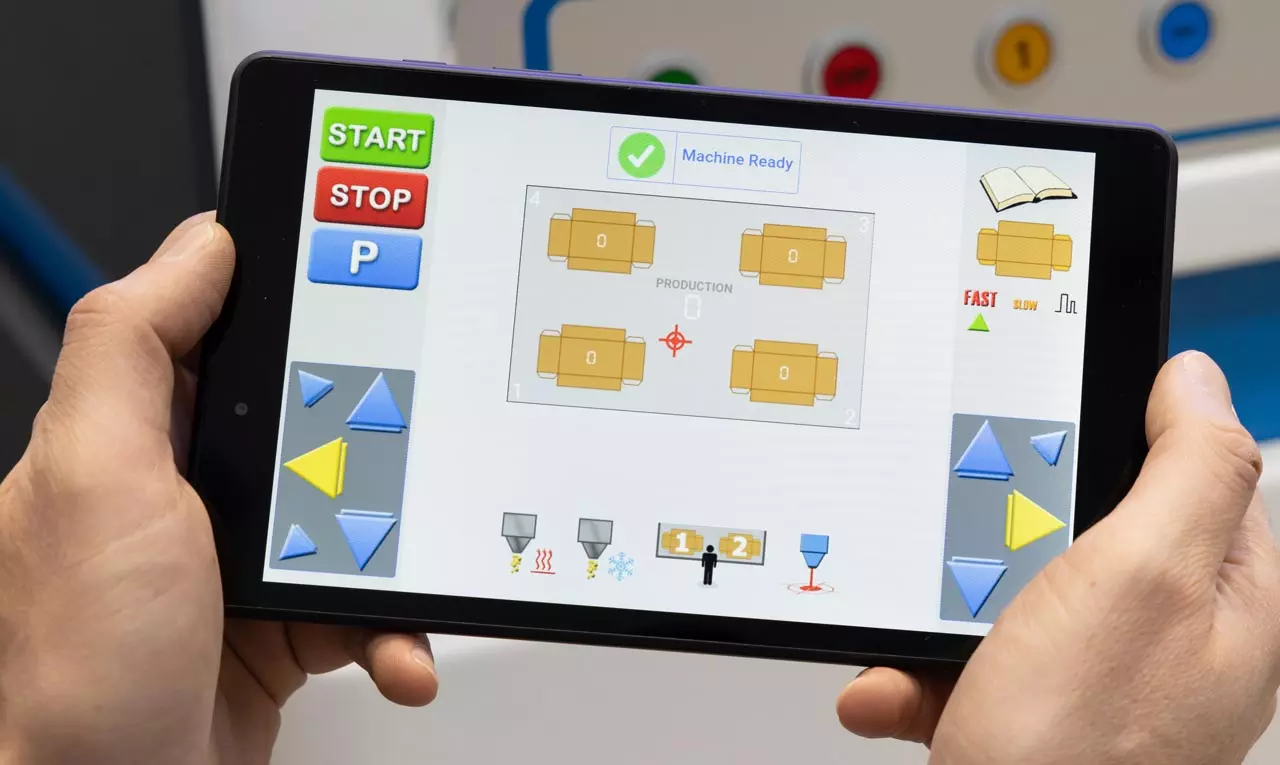

A machine designed to automate the gluing of display units, display stands, crowners and pall boxes. Its strength lies in its versatility. Easy to programme, it will fit into any gluing department seamlessly, causing minimal disruption to the department as installation and operator training can be performed in a single day. A company’s gluing department can be found at the end of a process that starts with the design of the display unit, followed by printing and cutting. Only once these stages have been completed can assembly and gluing take place. This means that any delays that occur during the previous stages have an impact on the assembly stage. To help counteract these delays, we have made the F SERVICE software simple to programme, ensuring that it is quick and efficient in organising the work, particularly when it comes to communicating timescales to the operators. This helps to optimise the workflow.

Faster and more reliable timescales

Flawless gluing quality from the first to the last piece, ensuring that the same amount of hotmelt and/or cold glue is deposited in the same time. This provides a further guarantee that the glue will hold, eliminating the risk of products being returned because they have come apart!

Increased production

the plotter glues at a speed of 2 metres per second and also informs the operators of the timings. Breaks are adjusted so that the next piece is ready as soon as the previous piece has been assembled.

Guaranteed advantages

Phoenix will allow you to make up for delays in previous stages of production, improve the quality of the product offered to your customers, and, very importantly, predict timescales accurately right from the design stage (yes, you read that right!). Thanks to our software, which can be installed on any PC, you can manage the quote for the gluing process before even putting the piece on the plotter, helping you to control your costs.

Phoenix is TECHNOLOGY

Thanks to our software, which can be installed on any PC, you can manage the quote for the gluing process before even putting the piece on the plotter, helping you to control your costs.

Phoenix is

THE FASTEST

PLOTTER

Characteristics

work area: 2700 x 1750 mm | elevators area: 2700x1750 or 1350x1750 mm |

gluing speed: 2 m/s | teleservice: Industry 4.0 |

motors: 3 brushless motors | Hot melt system: with gear pump (capacity 5/10/15 kg) |

axes: high performance XY | vinyl glue system: with pneumatic pump |

programming: tablet with F Service app | guns: Zero Cavity |

workstation: 4 |